Qingdao SOSN Machinery Co., Ltd. is one of the most reliable manufacturers and suppliers of cnc engraving machine in China. Please feel free to buy CE approved cnc engraving machine for sale here from our factory. Quality products and reasonable price are available.

Production Introduction:

We offer a CNC engraving machine.

Four spindles CNC engraving machine is commonly used in the market and can be used for both cabinet and cabinet door engraving.

Equipped with 4 spindles, this machine allows you to carry out cutting, drilling, slotting, and grooving without having to change tools, which highly improves the production efficiency.

Servo drive system

Imported components, such as France Schneider electronics, have stable performance.

Product Parameter:

|

Workable processing |

1300X2500X200mm |

|

Working size |

1220X2440mmx150mm |

|

Resolutions |

±0.05mm |

|

System Resolution |

±0.001mm |

|

Repeat Positioning Accuracy |

±0.03mm |

|

Max. Working speed |

15m / min |

|

Traveling speed |

60m / min |

|

worktable Structure |

vacuum worktable |

|

Shaft Drive Mode |

X/Y rack; Z lead screw |

|

Servo motor |

INVT Servo motor |

|

Control system |

LNC (Easy to learn) |

|

Max Travel Speed |

100m/min |

|

Spindle power |

6kw*2 + 2.2kw*2 |

|

Spindle Speed |

24000r/min |

|

Operating Voltage |

380V/50HZ |

|

Run Command |

G code |

|

vacuum pump |

7.5KW |

|

Machine weight |

2300kg |

|

Overall dimension |

3500*2400*2400mm |

|

Workable processing |

1300X2500X200mm |

Product Feature and Application:

Application :

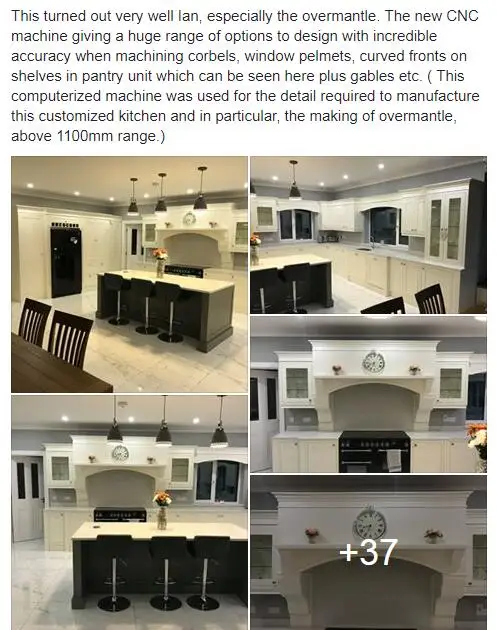

CNC engraving machine used on wood, MDF, acrylic, PVC, plastic, and other materials.

Feature:

CNC engraving machines are welded with a thick-walled 10mm square tube, which provides high strength and stability with no deformation; and the tempering treatment ensures that the whole machine is not deformed in a long time using;

CNC engraving machines have 4 spindles, the spindles can be changed automatically for different works, saving much time and greatly increasing the working efficiency; It can realize cutting, engraving, drilling, routing, grooving.

Product Details :

1) High Version LNC Syntec system is easy to learn.

(Syntec system optional)

2) Equipped with 4 spindles, this machine allows you to carry out cutting, drilling, slotting, and grooving without having to change tools, which highly improves the production efficiency.

3) Heavy-duty profiling with an annealed machine body for precision and stability.

4) High precision linear guide rail, and the lifetime of a linear guide rail is 10 times longer than that of a round one.

5)Vacuum table and pump: The vacuum table is multi-zoned which allows the operator to easily switch from full sheet processing to smaller part processing. It can be partitioned according to customers' needs, and each area can be controlled separately. Gas consumption can be controlled.

6)Machine central oil lubricator: Easier to lubricate regularly and automatically.

7) The pump body of the vacuum pump adopts a separate structure, which is convenient to maintain. It has higher strength, better toughness, and plasticity than the ordinary vacuum pump.

8)About our own Company

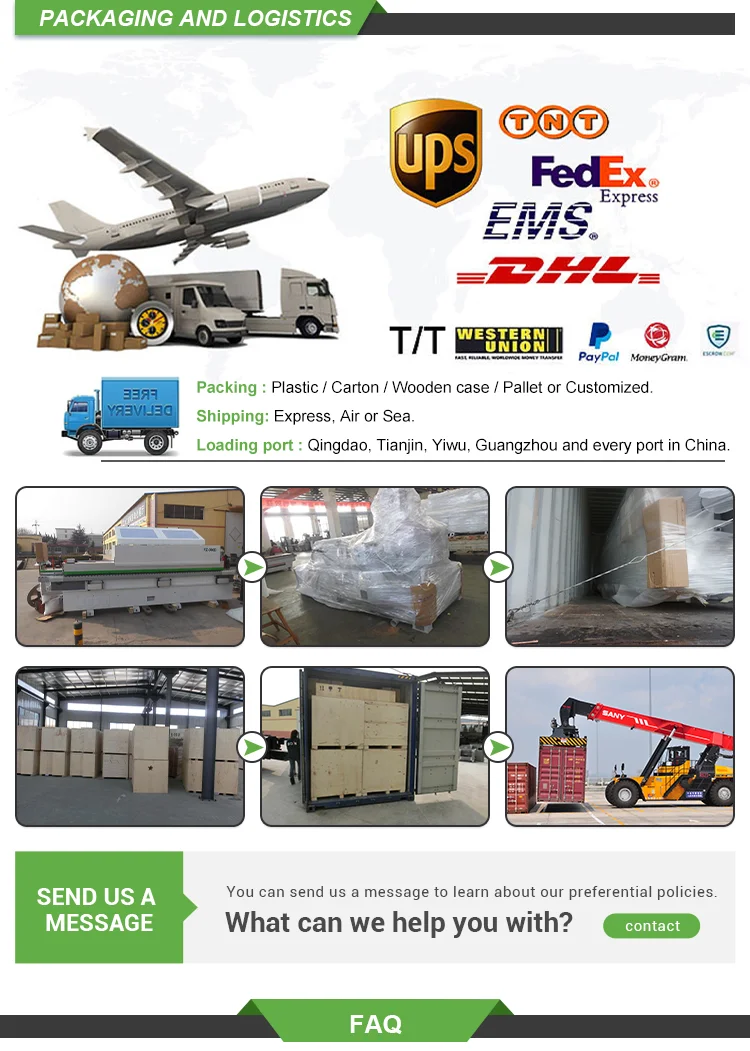

9)Standard export packaging, stretch film packaging, wooden box packaging can be requested if LCL transportation is required.

10)Other categories of products

In addition to CNC engraving machines, SOSN also has other CNC products, such as computer panel saws, four-sided saws, edge banding machines, six-sided drilling center, PTP, etc., which can meet your different needs.

Product descriptions from the supplier

plywood, chipboard, MDF, etc.

Double layers vacuum absorption working Table can be customized size.

Various solutions to meet the specific needs of flexible production.

Heavy duty profiling, machine body with annealing for precision and stability.

|

Over all size

|

3600*2600*2000mm

|

|

Working size

|

1220*2440mm

|

|

Working area

|

1220*2440*150mm

|

|

Max speed

|

60m/min(MAX)

|

|

Working speed

|

15-20m/min(MAX)( depends on materials and thickness )

|

|

Voltage

|

AC380V/3PH/50HZ

|

|

Main spindle

|

WHD 9.0kw or CC 9KW (24000r/min) depends on delivery time

|

|

Body frame

|

Annealing and finishing milling a molding process, stable structure, high precision, small deformation

|

|

Drive system

|

INVT SERVO

|

|

Gear rack

|

Taiwan alloy hard tooth face helical rack + alloy hard tooth face helical gear

|

|

Guide

|

30

|

|

Control system

|

Taiwan LNC system

|

|

Locate mode

|

High precision automatic positioning cylinder

|

|

Table structure

|

Strong Vacuum worktable

|

|

Electrics

|

French Schneider

|

|

Inverter

|

Fuling

|

|

Vacuum pump

|

7.5 kw water vacuum pump

|

|

Cable

|

shanghai BOSHI flexible towline cable (with shield)

|

|

Air components

|

BLCH

|

|

Vacuum pump

|

7.5 kw water vacuum pump

|

|

Weight

|

2.4 Ton

|

requirements, highly versatile with routing, drilling, cutting, sawing, slotting and other functions.

2) with 12 carousel type tool. By changing different tools automatically, this machine can complete multiple and complex processes at one operation. It can realize cutting, engraving, drilling, routing, grooving, and pocketing of wood, MDF, acrylic, PVC, plastic, foam, and other materials.

3) The first choice for enterprises with large production volume. Compared with the traditional manual

tool change production method, this type of wood CNC machine has an independent tool magazine with different tool bits. It can automatically change the required tools by computer program control without stopping work during processing.

Machine can be customized according to customer requirements.

Wood products such as speaker, game cabinet, computer desk, sewing machine table, Musical; Instrument; plate processing such as insulation, plastics and chemical items;

PCB; EMU body,bowling track; special anti-fold panels, epoxy resin, ABS, PP, PE and other carbide mixture; and milling,cutting,processing of graphite, acrylic, PVC, density board, plastic, aluminum,copper and other soft sheet metal ornamental in Decoration industry.

drive, faster and more accurate.

Why choose us?

- Our products and services are backed by a solid warranty and after-sales support.

- We are developing rapidly with a fast, healthy and sustainable trend, and are dedicated to providing safe, reliable and high-quality products for our customers.

- We are committed to providing innovative solutions to meet the evolving needs of our customers.

- Our team members have international background and experience, and can provide you with good service.

- Our experienced sales team is dedicated to supporting our customers throughout the entire process.

- With high-quality products, perfect service, novel design and unique concept, our product quality and service have been recognized by many domestic customers.

- Our products and services are designed around the needs of our customers.

- Welcome to call for more product information, we sincerely look forward to your choice of our CNC Engraving Machine and believe that the quality of our products will make you satisfied.

- Our company is dedicated to providing top-notch products and excellent customer service.

- "Building a model in the industry and becoming a century-old company" is the common vision of CNC Engraving Machine people and the highest program for enterprise development. Set a model in the industry, thereby creating new industry standards, and becoming a leader in the industry; to be a long-term company to achieve sustained, rapid and stable development of the company.

Hot Tags: cnc engraving machine, China cnc engraving machine manufacturers, suppliers, factory, CNC Engraving Machine, ATC CNC Router Machine, CNC Router Milling Machine, CNC Router Cutting Machine